功能特點

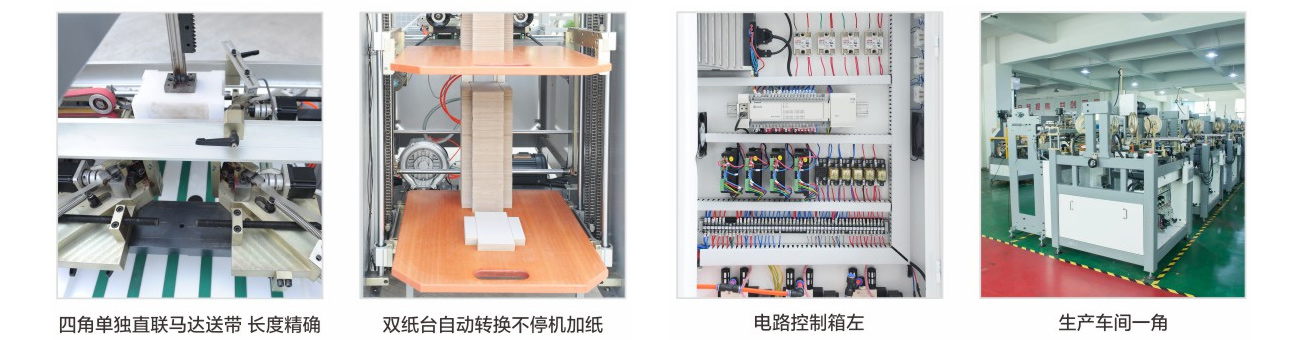

1.飛達送板:更適合(hé)對厚板,薄板、變形板,特(tè)大板,開槽板的四角(jiǎo)貼角。有紙盒下拉與自動定位機速度自動匹配(pèi)功能,

2.雙升紙台:方便操作工提前堆紙(zhǐ),提高生產效率,降低工人勞動強(qiáng)度。

3.合金膠帶槽:裝配精度高,永(yǒng)遠不變形,有效避免堵帶、粘(zhān)帶等常見問題。

4.整體機架:大型加工中心一次加工成型,機架橫梁,刀座之間(jiān)平行(háng)度垂直度誤差(chà)0.MM以內, 裝配精度可以保障,所有換模調(diào)機時非常容易。5.進口(kǒu)導軌滑塊:貼角、調節處由台灣(wān)上銀品牌導軌導向,很容易獲得最佳精度要求。

6.馬達控製主軸(zhóu)和送膠帶:貼角位置由觸(chù)摸屏設置,可貼一次或多次。馬(mǎ)達送膠帶,所需長度任意調整,並(bìng)且有停機倒帶防粘連功能。

Functional features

1. Cardboard fedng more suitable for thick board, thin board, defomation board, bid board and grooving board comer taping m match with pull box and malch sotter

2. Double Paper feding abl: worker can pile paper advanced, improve felively and reduce the labor ntensity

3. Alloy tape groove: assemble accuracy is high, never deformation, fflciveley avoid tape block and sticky.

4. Overall frame: Large CNC center one processing molding. Rack, beam, knifo holdor eror is 5. Mm assembly accurale can be guranteed . the mold change svery easy.

5. Import rail side: taping and adjust part rail is Taiwan brand. it can make sure the precision

6. Motor control main axis and tape feding taping locaton sting by touch screen, can tape one tme or mary tmes. And tape lengh can be adlustable. And stop rewind, anb adhesin funcion.

微信公眾號

微信公眾號 微信小(xiǎo)程序

微信小(xiǎo)程序

微信公眾號

微信公眾號 微信小(xiǎo)程序

微信小(xiǎo)程序

手機網站

手機網站